Все продукты

-

Тени жаккарда сплетя

-

Электронная тень жаккарда

-

Голова жаккарда

-

Завершите проводку жаккарда

-

Шнур проводки жаккарда

-

Рекондитион тень ярлыка

-

Рекондитион сплетя тень

-

Электронный регулятор жаккарда

-

Изменение для машинного оборудования ткани

-

Тень воздушной струи

-

Тень рапиры сплетя

-

Автоматическая тень челнока

-

части сплетя тени запасные

-

Машинное оборудование ковра сплетя

-

Части машины ярлыка

-

части машины жаккарда

-

Машина пряжи снуя

-

Машина для обуви

-

Режа и складывая машина

-

Машина для вышивки иглы

-

Нитка из полиэстера

-

AlgerПродукт очень хорош и качество очень хорошо. Я куплю его назад.

AlgerПродукт очень хорош и качество очень хорошо. Я куплю его назад. -

БаронПриведенная машина очень хороша, и качество это же как новое одно.

БаронПриведенная машина очень хороша, и качество это же как новое одно. -

ДэннисКачество машины жаккарда очень хорошо и было порекомендовано к друзьям.

ДэннисКачество машины жаккарда очень хорошо и было порекомендовано к друзьям.

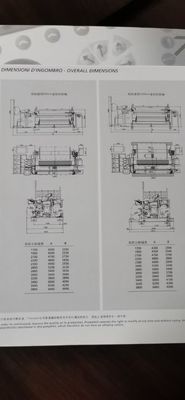

Customizable Flannelette Weaving Machine for Home Textile & Apparel Production

Подробная информация о продукте

| Размер | Различные размеры доступны | Высота открытия | 50-120 мм |

|---|---|---|---|

| Приложение | Текстильная промышленность, DIY-проекты | Использование | Ткачество ткани |

| Гарантия | 1 год | Дизайн | Замысловатые узоры |

| Тип | Механический | голова джаккарда | Китайский или Staubli или т. д. |

| Ткань | Этикетка, галстук, ткань, кружево, бренд руки и т. д. | Цвет | зеленый |

| Функции | Регулируемое натяжение, несколько челноков, простота в использовании. | Модель | Сплетя тени |

| Состояние | Новый | Масса | 1,5-2,5 тонны |

| Материал | Дерево/металл |

Характер продукции

Порекомендованные продукты